Street Rodder Road Tour–Nose Job

Dating back to the ’50s, car customizers have been trying to beautify vehicles in every way possible. Rounding corners, smoothing edges and lowering the car’s silhouette are common goals in the custom world, and one sure fire way to do it is to modify the hood for a sleeker appearance. We set out to do just that with the Street Rodder Road Tour car, and the results were certainly worth the effort. A few days of cutting, shaping, welding and grinding took the ’51 Ford’s big schnoz and turned it into a stylish nose. Keep reading to see how we did it!

Surprisingly, the hood had very little rust to deal with, so it’s yet another case of cutting up the only good steel left on this ’51 Ford. Richard and Delton made their marks prior to cutting.

An electric grinder with a cut-off wheel makes easy work of cutting a rather large hole in the hood. If you wanted to do a minor nose job, you could even re-use the piece that we’re cutting out right now. We will be fabricating a whole new piece to create a new contour.

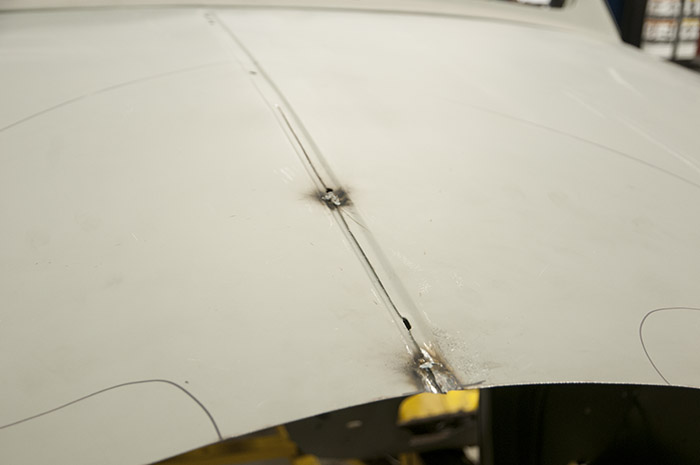

With a gaping hole in the hood, Richard cut a slice down the ridge in the middle of the hood. This relief cut allowed the hood to relax, which gave the hood a natural and gentle slope.

The relief cut in the middle of the hood caused an overlap in the metal when the hood relaxed. We trimmed the overlap and tack-welded the two halves to get a baseline measurement.

This is the result of our relief cut down the middle. With the middle of the hood relaxing down, we decided on our next move to get the shape where we want it.

To get the shape right, we fed the hood into our shrinker/stretcher…this obviously isn’t a one-man job, so Jonathan Myren stepped in to help.

With the hood shaped to our liking, we used foam to fill the gigantic hole. Then we shaved the foam to the shape we want. This isn’t totally necessary, but it gave us an idea of the finished look, and it gave us a pattern to build our wooden buck.

The foam is shaved to our desired shape, so we placed a cardboard pattern of the original hood shape for a comparison.

A wooden buck was built and temporarily mounted to the hood. Richard and Delton can use this to shape the fresh steel, making sure that both halves match.

Using our Eastwood shrinker/stretcher tools, Richard and Delton shape the two halves of the new nose. We will make the peaked center portion of the hood in a separate piece.